After walking the fields last week and seeing the bright red clusters of cherries flaunting their color from under the thick green leaves, we began thinking about the journey the cherry makes once off the tree. Brix counted, plucked from the branches at just the right moment, and placed on trucks, where do they go? Precious and perishable, they require special care that befits their short-term, sexy, seasonal status.

On a warm, blue sky afternoon, Aileen, Shelley and I navigate our way through the Washington Fruit buildings and park under a giant neon cherry signaling that this is the place for cherry packing. We step inside. The large open space is bright, cool, and clean. Boxes descend mysteriously in long rows from holes in the ceiling, like kite string, as cherries are being packed up, but this is the end of the line. We want to walk the line from where it starts. Fortunately, the System Operator, Mikey Hanks, is there to show us around.

In the beginning, there were reefer trucks–refrigeration that is. The cherries arrive from the fields in refrigerated trucks where they are unloaded at the warehouse, which itself is kept pretty chilly. They are immediately given a cold shower in the hydro-cooler, and then they’re off and running.

In the beginning, there were reefer trucks–refrigeration that is. The cherries arrive from the fields in refrigerated trucks where they are unloaded at the warehouse, which itself is kept pretty chilly. They are immediately given a cold shower in the hydro-cooler, and then they’re off and running.

Temperature is the key to keeping cherries looking good. In the absence of low temps, a cherry will go bad in 2-3 days, so time and temperature are of the essence. Mikey explains that the fruit is picked, packed and shipped within 24 hours.

Flow is the best way to describe a cherry run as there are few conveyor belts. The fruit is pushed by waterpower through various chutes, with gentle curves instead of hard angles, to keep them cold and move them along.

Flow is the best way to describe a cherry run as there are few conveyor belts. The fruit is pushed by waterpower through various chutes, with gentle curves instead of hard angles, to keep them cold and move them along.

Maintaining water quality is a very large part of the process. In lieu of white gloves, clean and cold moving water is the treatment these luscious red divas receive as they travel the line.

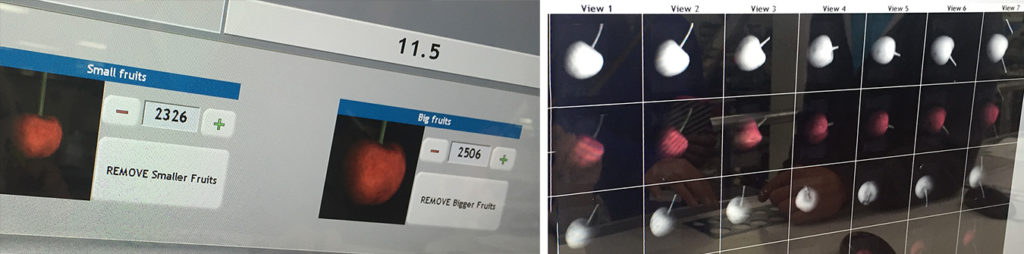

Leaves are separated because they float and cherries sink, clusters are gently broken taking care to leave the stems intact. At the end of all this prep work, the cherries are ready for inspection.  After a short series of belts that get progressively faster to put them in a single file line, the fruit runs through a machine which photographs each individual cherry with four different cameras assessing color quality and surface defects. A fifth camera gets a picture from side to side where an exact pixel count determines size. They are graded accordingly, and a quick puff of air blows them off the line and into their assigned group of similarly judged fruit.

After a short series of belts that get progressively faster to put them in a single file line, the fruit runs through a machine which photographs each individual cherry with four different cameras assessing color quality and surface defects. A fifth camera gets a picture from side to side where an exact pixel count determines size. They are graded accordingly, and a quick puff of air blows them off the line and into their assigned group of similarly judged fruit.

Now they can be packed up. Workers are in charge of the final review, plucking out any debris or blemishes the cameras miss. In the end, they are weighed, bagged and boxed from the now, not-so-mysterious area upstairs where boxes are assembled and sent downstairs on tracks through holes in the floor explaining the kite string rows of boxes on the ground floor.

Now they can be packed up. Workers are in charge of the final review, plucking out any debris or blemishes the cameras miss. In the end, they are weighed, bagged and boxed from the now, not-so-mysterious area upstairs where boxes are assembled and sent downstairs on tracks through holes in the floor explaining the kite string rows of boxes on the ground floor.

Next stop, the eager markets of the world, where everyone wants a delicate, sweet bite of the short-term, sexy, seasonal harbinger of summer. Brought to you by lots of care, cold water, and some serious technical savvy.

A big thank you to Clifford Plath for setting us up, and Mikey Hanks for taking the time to show us around!

Born nd raised in Cowiche lived here all but 7 months of my life. Thank You for this great article. Intreresting how the handling of the cherry has changed as have the orchards and harvesting.